Originally

Here in the West we inherit, in terms of perfumery, the know-how of the Egyptians. They will establish the bases of the two modes of extraction which will evolve over time thanks to technology and the genius of man. One using aqueous distillation and its derivatives. The other using fat, oily macerate and its derivatives.

Distillation

To distill is a word that comes from Arabic which means to separate. We first capture the vapor of the water, then the essence of the fragrant materials of the plant and finally we separate the essential oil from the floral water.

Distillation is done using the still, a device designed to separate products by heating and then cooling.

1500 BC. JC

A calabash serves as a container, it is coated with moist clay to protect it from the flames. Inside, the fragrant product of flowers, seeds or woods mixed with water, the whole covered with a linen or cotton fabric or a woolen fleece. When the fabric is soaked in the fragrant vapor, it is wrung out and a floral water is obtained.

A millennium later

The Greeks will replace the calabash with a terracotta pot, enamelled on the inside. The ancient Greeks will be the first to extract citrus fruits. People of sailors, they will help themselves to products from the sea. Using a pumice stone, they will grate the zest of the citrus skin over a sea sponge. Once wrung out, they will directly obtain the essence of citrus.

1st millennium AD

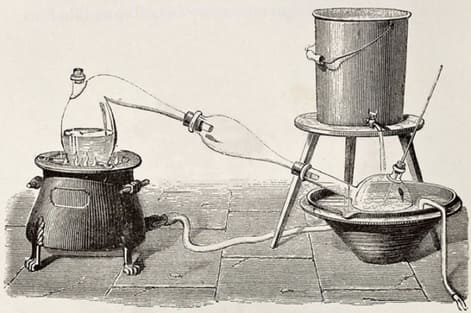

Avicenna, philosopher, writer and doctor of Persian origin, considerably improves the still which will henceforth be made of copper. Avicenna will perfect it by adding the swan's neck for the lid, which he will connect to a cooling tank by a serpentine-shaped copper pipe.

The coil is in the cooling tank, full of cold water, constantly renewed, which allows the vapor loaded with odorous molecules to cool down and thus be able to be captured. The floral water and the essential oil are collected in a vase located below the cooling tank.

The still is now composed of three parts: the tank with the fragrant materials, the cooling tank which contains the coil and the vase which will later be called "florentine" which allows the recovery of the essential oil.

Since the XNUMXth century in Provence, aromatic plants were picked and druggists-peddlers traded in them. From the XNUMXth century, the pickers distilled on the places of picking. Today, you can see the chimneys of many small distilleries emitting fragrant smoke over the hills of Provence, especially in Haute-Provence. These are often basic hangars that house equipment that has become sophisticated with stainless steel tanks. Since May, they have been distilling first Thyme, Tarragon in June, then Lavandin at the beginning of July, Fine Lavender at the end of July, Clary Sage in August, followed by Fennel, and Savory in September. At the end of the season in October, a final distillation was done with the Parietaire, the plant of the walls, which made it possible to descale, to clean the still for the following year.

The birth of Hydro-distillation – XNUMXth century

Perfumers are becoming more demanding when it comes to the quality of the distillation. The still will improve. The tank will now contain a basket in which the materials to be distilled will be placed. The plants will no longer be in direct contact with the water but will be traversed by the steam. This one charged with odorous molecules will follow its way in the neck of the swan where the carbonic gases of the steam will mix with the odorous molecules. Everything will be cooled in the circuit of the serpentine and will be recovered in the Florentine vase which receives both the floral water and the essential oil which floats on the surface. A spout, tap located at the top of the vase allows you to recover the essential oil while the tap placed at the bottom of the vase allows you to recover the floral water or the hydrosol.

Cohobing

Due to the low yield obtained by certain fragrant materials such as for the rose (a 1/5 of the final product) we will carry out a second distillation with the remaining floral water, this stage is called “cohobage”. A second oil is then obtained (the remaining 4/5) with a different olfactory profile but also containing phenylethyl alcohol. After filtration of the oils, they are mixed to obtain more yield.

Namely: the processes of distillation and hydrodistillation require heating the raw materials, the molecules recovered in the essential oil will be artefacts of the molecules present in the natural state of the plant. These differences are due to the degradation of the raw material that is not found in the natural state of the petal. In other words, an essential oil of a rose or any other flower will never have the precise smell of a rose on its rosebush. Essential oils obtained by hydrodistillation only are used in aromatherapy, because they are considered natural materials, while solvent extraction is only intended for perfumery.

The turbo distillation

An alternative to too long hydrodistillation which alters the essential oil because of the heat, as is the case for the distillation of iris which lasts up to 30 hours. The material is placed in the distillation tank with boiling water. This tank is equipped with a turbine allowing the constant agitation of the vegetable matter. This process increases the contact surfaces between the material and the water vapour, the distillation time is reduced and the yield is improved.

Plants concerned are Iris, star anise, and celery seeds.

The cold expression

This technique is reserved for citrus fruits, it does not require heating, unlike distillation. The product obtained is therefore faithful to the smell of the raw material, slightly denatured, with no cooking artefact of the molecules. Industrialization will imitate the gestures and physical principles that the ancient Greeks did by scraping the zest with the pumice stone and recovering the essence directly by squeezing the sponge. In an extractor which contains large grating discs the citrus fruits are put inside. By electricity, the machine turns these graters which extract the essence contained in the secretory pockets on the zest of the fruit. What comes out is called essence and not essential oil.

The infusion

In perfumery, this process consists of maceration in pure alcohol in order to cold dissolve the soluble principles of a solid or pasty raw material of animal (musk, amber) or vegetable origin (tonka bean, iris, oak) This operation is carried out over an extended period of several months.

Volatile solvent extraction

This method takes place in three stages, a- washing the flowers with a solvent, b- evaporating the solvent to obtain a paste and finally c- washing the wax to obtain the absolute.

This technique consists of placing the flowers in a large tank called an “extractor”. The content is then passed to the solvent, hexane is preferred. Highly volatile in nature, hexane will “carry” odorous molecules out of the plant. This washing is carried out three times in succession at low temperature to capture the maximum number of olfactory compounds. The scented solvent is recovered. Under vacuum, the solvent is brought to a boil, which will allow it to evaporate. This leaves us with a fatty substance made of wax impregnated with the odorous molecules of the plant, which solidifies in the open air and at room temperature. This paste called "concrete" is then washed and purified with alcohol. The alcohol is then removed in a concentrator. In the end, all that will remain is a liquid called "absolute". Plants concerned: all delicate materials, such as jasmine, orange blossom, tinka bean, mimosa, etc.

enfleurage

This method is no longer in use but it is mythical, it is intrinsically linked to Grasse perfumery. She made her reputation around the world.

This process consisted in letting the flowers macerate in a layer of odorless cold fat, prepared during the winter, on glazed frames, which would be stacked on top of each other. These piles could reach 3-4m. height. The flowers were changed regularly, which explains the large workforce and the quantity of flowers requested. Once the fat was saturated with odors, it was heated to a very low temperature and filtered. A solid perfume was obtained which was then washed with alcohol in order to dissolve the fats and reveal the odorous molecules.

Super critical CO2 extraction

Developed in the 70s, it is a method that faithfully restores the smell of plants. Supercritical CO2 extraction is based on the compression of carbon dioxide that is sent to the tanks that contain the raw material, until it reaches the state of fluid. In this supercritical state, the gas acts as a selective solvent, entraining the compounds it dissolves. Once the compounds have been recovered, the CO2 becomes gas again by depressurization and leaves no residue in the extract.

Odorless, non-polluting, non-toxic, supercritical CO2 is increasingly used for the extraction of plants as an ecologically viable alternative to organic solvents such as hexane. Since the process temperatures remain relatively low at 31°C, the odorous compounds are not altered by the heat. It is mainly used for spices. Faithful to the principles of green chemistry, as well as to the original aromatic profile of the plant, CO2 extraction is acclaimed by certain brands anxious to give a certain non-polluting image. It is compatible with organic farming, however it has an energy cost due to gas compression.

Component analysis

Over the years, new techniques have emerged to analyze plant components.

Gas Chromatography – Year 50

This method, introduced at the end of the 50s, is not used to extract a product from the plant but makes it possible to identify and separate the molecules of a very complex mixture of very different natures and volatility. The application of this technique allowed in the 60s the identification of the components of essential oils and this in a very accelerated way. An example with the rose in 1950 we knew in the rose 50 molecules, 200 in 1970, 400 in 1990. Chromatology is also used to identify and quantify the components of perfumes on the market. This technique is used in all perfumery laboratories.

The headspace – Year 80

To meet consumer demand for ever more naturalness, the perfume industry will hijack a technique used to analyze the composition of gases in the search for oil, so that the perfume gives the illusion of a flower. alive. A glass bell is installed in the open air, a flower is imprisoned there to analyze and identify its molecules. The smell of the flower is moved by a gas stream before being imprisoned in an absorbent cartridge which will allow its chemical formula to be reconstituted in the laboratory.

Micro-extraction – Year 90

Solid phase micro-extraction is more manageable than headspace. Thanks to a portable syringe that captures and concentrates the volatile compounds to be analyzed. This technique does not require solvents or complicated equipment.

second millennium

Nothing stops progress, “living perfumes” are a new step in innovation to capture a smell and give the impression of life. Givaudan, creator of synthetic scents, perfumed preparations, laboratory and veritable hive of perfumers, sends a "high-tech equipped" hot-air balloon into the air to capture the scent of rare flowers blooming on the tops of tropical trees...

So with these examples, perfumery is definitely an art in motion. Each year a large number of new fragrant molecules will be introduced into the perfumer's palette and will give rise to new creations. Some perfumers have a range of 2000 or 3000 notes to astonish and please an audience that is ever more demanding in terms of olfactory sensations. Definitely the perfume twirls.

Based on research by Tachka Sofer.

End of the Virevolte adventure

Do not hesitate to consult the list of our resellers if you wish to buy one of our perfumes.

Julie Desoomer